The 2000BPH water bottle manufacturing machine is suitable to produce differently shaped bottles from PET hollow hard tube. It is widely used to produce water bottle, beverage bottle and oil bottle.

fob price $ 14,300.00

What this price included:

| 1 | 9 | 1 SET |

| 2 | Rotating oven; | 1 SET |

| 3 | HP & LP Air compressor; 1.5M3/min 30KG | 1 SET |

| 4 | 0.6m3 Air Tank | 1 SET |

| 5 | Refrigeration Air Dryer; 1.0M3/3.0Mpa | 1 SET |

| 6 | Air filter 1.5m3/min 30KG | 2SET |

| 7 | 4Cavity blow mold (200-2000ml) | 1SET |

| 8 | Mold Air-Cooling (Cooling the mold to make sure machine continued running) | 1SET |

| 9 | Spare part | 1SET |

One blower with 4 Cavity

The blow mold have 4 cavity. It can produce 4 piece plastic pet bottle once. Because of mold size limit. Its only can produce biggest plastic water bottle is 1 liter.

More High Speed With Lesst Cost

Its capacity of production can reach 2500 bottles per hour which is as faster as automatic blow molding machine. But its cost only 30% of automatic blow molding machine. It half bottled water company save large number of invest on the blowing machine.

Automatic fall down bottle

After produced plastic pet bottle. The water bottle manufacturing machine will auto fall the plastic pet bottle down through an passageway. So that can easy collect plastic water bottle.

Save Labor With Less Cost

Its design automatic fall down plastic bottle system which save large labor cost. And what is more, it cut an moving bottle step. So it can increase the machine capacity of production.

Technique Parameter of the water bottle manufacturing machine

| Product material | PET |

| Volume | 200ml 333ml 500ml 555ml 600ml 700ml 750ml 800ml 1000ml It can not use to produce bottle big than 1liter |

| Theoretical output | 2500PCS/H, Once produce 4psc bottle |

| Preform length | 55mm-150mm |

| Preform inner diameter | Φ20mm-30mm |

| Max. mould plate Dimension (L x W) | 460×330×160MM |

| Max. mould thickness | 180mm |

| Clamping force | 45KN |

| Mould opening stroke | 160mm |

| Main machine (L x W x H) | 1660x820x2150MM |

| Main machine weight | 1000Kg |

| Heater (L x W x H) | 2160x580x1350 |

| Heater weight | 300Kg |

| Power | 26kw |

advanced water bottle manufacturing machine

It has the advantages of energy-saving, small size, low investment, (fast money back), efficient, and reasonable structure and is widely used in food, medicine, cosmetic, pesticide-killer, chemical and beverage packaging industries.

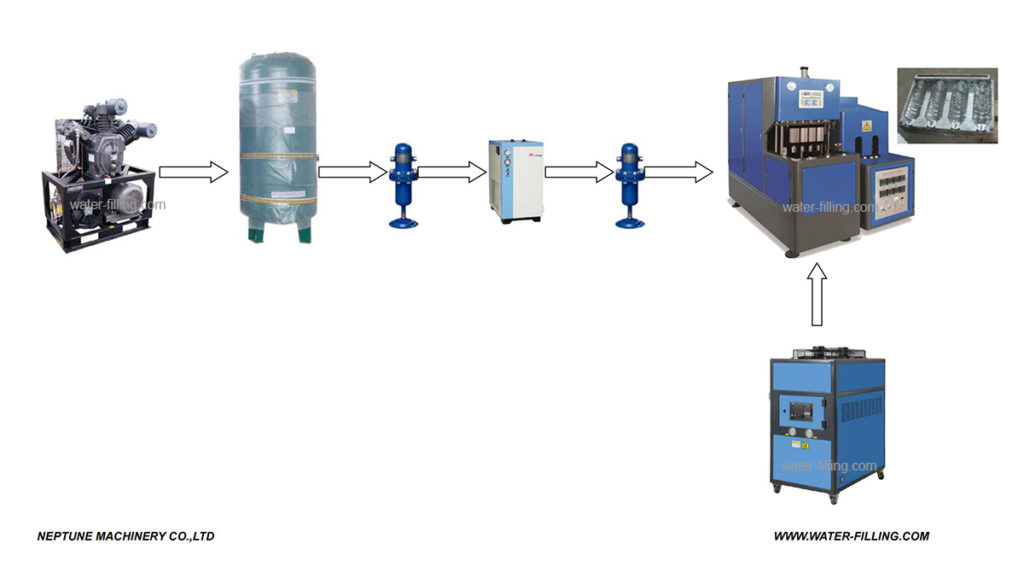

Air compressor offer high pressure air both for machine blowing and opretion. For air pressure stable, so that need an air tank for storage air. Because of the air is use for blow plastic bottle, if dirty will pollution inside of the plastic bottle. So need air filler and air dryer, then add another air filter after air dryer. If weather is hot and factory hot, and long time use mold is super hot. So that need fit an mold-cooling to cool the mold. Use air type mold cool will not pollution factory floor with an lot water. Just an little expensive than water mold cooling.

Whole Blow molding Machine running process

Character of 4 cavity plastic bottle manufacturing machine

1. Microcomputer control, easy to operate.

2. Heating part is IR heating tube, controlled by imported controlling silicon. The moving part is equipped with three phases motor, and drived by frequency changing part.

3. There are left and right cylinders in sealing stretching part. the stretching length can be adjusted automatically, and the time for air blowing can be adjusted freely. the bottle blowing can benefit from doing so.

4. The waste air can be exhausted from a silencer inside the machine. It reduces the possibility of creating water drop, and is prevented from making noise.

5. There are two air storage barrels inside the main machine and one high, one low, pressure-reducing valve.

Related Machine

FAQ

How does the blow molding machine work?

It is made use of air pressure to blowing heating well preform into idea plastic bottle, And because preform in the idea mold, so that final plastic bottle shape decide by the mold.

Worker need manual insert preform on heating oven. And got the heating well preform to the blowing machine. Then press the button and blow the air into the preform. So that the preform will blowing into idea plastic bottle according the bottle mold.

What Is Materials Of Blow Molding Machine ?

It is a hollow hare tube which also called pet preform. The preform is molding by injection molding machine. The preforms are strong and small. 1psc 40HQ container can filler 600 thousands piece which is easy package and freight.