Best Bottled Water Filling Machine 2000BPH

fob price $ 13,000.00

Most monoblock bottling machine capacity is very big so that price is expensive. But a lot first start water bottling company do not need such big capacity. If buy those hig speed monoblock bottling machine which is waste money one extra capacity.

883 Bottled water filling machine aim at 2000bph capacity, so that just fit 8 psc filling head, 8 psc washing head and 3 psc capping head. It save materials cost so that the bottling machine for sale price is cheap.

883 Bottled water filling machine is a monoblock type bottling machine collect rotary rinser, filler and capper in one machine. It take small room.

- Every rinser head is moving synchronously with bottle while washing the plastic bottle. It working around 360 degree disk.

- Every filler head is moving synchronously with bottle while filling water into the bottle. It working around 360 degree disk.

- Every capper head is moving synchronously with bottle while capping the bottle water. It working around 360 degree disk.

Every valve finished working on one bottle and will moving to next bottle around the 360 degree disk. It is continued working without any stop.

It is fully automatic and save labor. Easy use and control by PLC.

It is the new water bottling machine. Little-know way to increase filling efficiency with less cost.

Parameter Of 8/8/3 Bottled Water Filling Machine

| MODEL | NF 8-8-3 |

| Production Capacity | 2000-2500 bottles/h |

| Washing Head Quantity | 8 |

| Filling Valve Quantity | 8 |

| Capping Head Quantity | 3 |

| Filling Temperature | Normal temperature |

| Filling Type | Constant Pressure Filling |

| Main Motor Power | 3.42KW |

| Bottle diameter | 40-102mm |

| Bottle height | 130-30mm |

| Air resource pressure | 0.5Mpa |

| Filling Water | 1-1.5T/H |

| Consume Water | 0.8T/H |

| Control Type | PLC |

| Central Diameter of Filling Valve | 320mm |

| Central Diameter of Capping Machine | 120mm |

| Central Diameter of Washing Machine | 320mm |

| Dimension | 1850 X 1450X2000mm |

| Net Weight: | 1200kg |

Video of the rotary bottled water filling machine

Its speed only 2000bottles per hour depend on 500ml bottled water. Production is very stable.

It is an best machine for people do not have experienced. All is setting well before out factory and do not need change any setting.

Rinser, filler and capper are all rotary type, So that whole machine is continued bottling water without any delay or waiting like linear type.

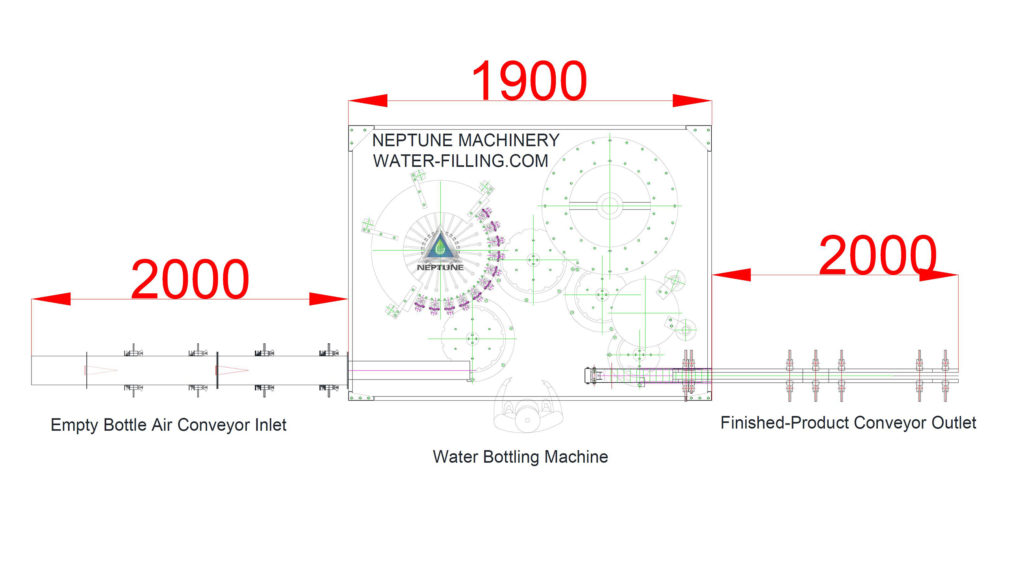

Layout of the 883 water bottling machine

8set catch bottle for washing bottle. The bottle are washing outside and inside by the flushing water from the moving washing head. 8 set filling valve filler pure water into the bottle and moving with the bottle together.

Then cap loading and feeding cap for every pass bottle water. 3 set magnetic twist full-tooth capping heads will screw bottle water with cap. It is automatic slip to ensure cap will not damaged by too much tightening.

What is complete set included ?

- 8-8-3 Bottled Water Bottling Machine 3-in-1 monoblock

- 2meter Empty bottle air conveyor inlet with fan

- 2meter Product conveyor belt with motor

Rotary filler

Rotary type filling machine is made use an 360 degree disk to let filling is continued and none any bottle need waiting other. Also rotary washing and rotary capping is continued without waiting.

Rotary Capper

The washing valve is moving with bottle while washing bottle. So that it is continued washing without any stop. The capacity of production is synchronization and really.

8-8-3 Water Bottling Machine Electrical Configuration

| NO | NAME | MODEL | UNIT | BRAND | NOTE |

| 1 | Main motor | Y90L-4 2.2KW | 1SET | China Suzhou | frame |

| 2 | Cover motor | YCJ90W-4 0.09kw | 1SET | China Taizhou | frame |

| 3 | Jet water pump | BJZ037S 0.376KW | 1SET | China Yuehua Pump | frame |

| 4 | Inlet pump | BJZ037S 0.376KW | 1SET | China Yuehua Pump | frame |

| 5 | Conveyor motor | UDL 0.37KW | 1SET | China Taizhou | frame |

| 6 | Air blower motor | Y802-2 0.75KW | 1SET | China Wuxi | frame |

| 9 | PLC | FX1S-20MR | 1SET | Mitsubishi | Electric control box |

| 10 | Inverter | FR-D740E-2.2K | 1SET | Mitsubishi | Electric control box |

| 11 | Breaker | DZ47-3P-D 20A | 1PSC | Schneider | Electric control box |

| 12 | Breaker | DZ47-1P –C6A | 1PSC | Schneider | Electric control box |

| 13 | AC contactor | CJX2-0910 | 6PSC | Schneider | Electric control box |

| Thermal relay | JRSD-25 | 6PSC | Schneider | Electric control box | |

| 15 | DC power supply | S-50-24V | 1PSC | China Taiwan | Electric control box |

| 16 | Terminal block | TD1545 | 1PSC | Tracy | Electric control box |

| 17 | Mushroom always stops | 01ZS | 1PSC | Schneider | electrical panel |

| 19 | Indicator light | AD16-22 | 1PSC | Schneider | electrical panel |

| 20 | Potentiometer | 1/2W 4.7K | 1PSC | China Shanghai | electrical panel |

| 21 | Touch screen | MT6070IQ | 1SET | China Taiwan Weilun | electrical panel |

| 22 | Proximity switch | PR18-5DN | 2PSC | AUTONICS | frame |

| 23 | Photoelectric switch | BR100-DDT | 3PSC | AUTONICS | frame |

| 24 | Cover feed motor | 0.37KW | 1PSC | China | cover delivery |

FAQ

What is rotary Water Bottling Machine?

Both Valve And Bottle Is Moving At The Same Time. And Every Washing Filling And Capping Valve Rotates At A Constant Speed Along The Circumference During The Bottling Process.

Rotary Water Bottling Machine Take Small Room And Speed Fast. It Is High Automaticlly And High Effective.

What is mono block Water Bottling Machine

It collect rinser, filler and capper in one mono block machine. Made use of rotary bottling technology. The bottling process is in an steel box which make sure the bottling environment clean. It is high automaticly and effective. It is the advanced water bottling machine in the world.

Why 883 mono block rotary water bottling machine

It is the smallest monoblock three in one water bottling machine in the world design by NEPTUNE MACHINERY. It is control by PLC and high automaticly. Tight structure and take small room. Because just aim at 2000 bottles per hour speed so that materials cost less. It is best water bottling machine to first start water bottle business.